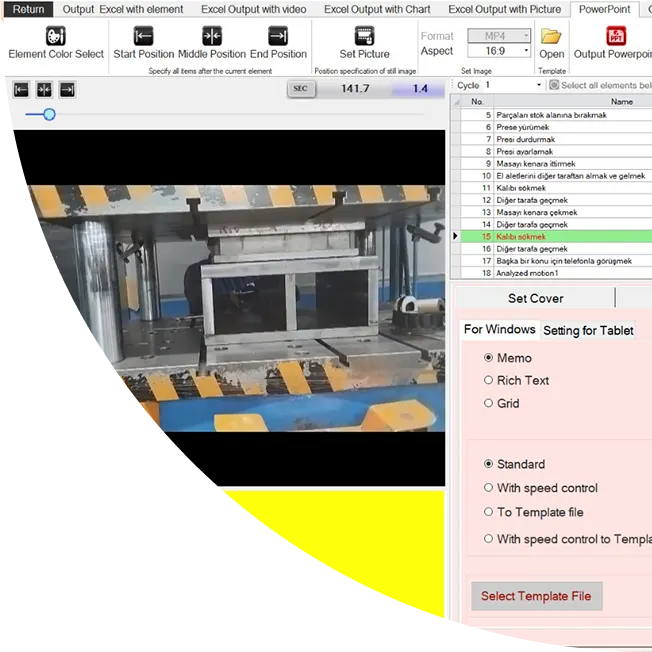

Record Video, Analyze Identify the Problem, Standardize

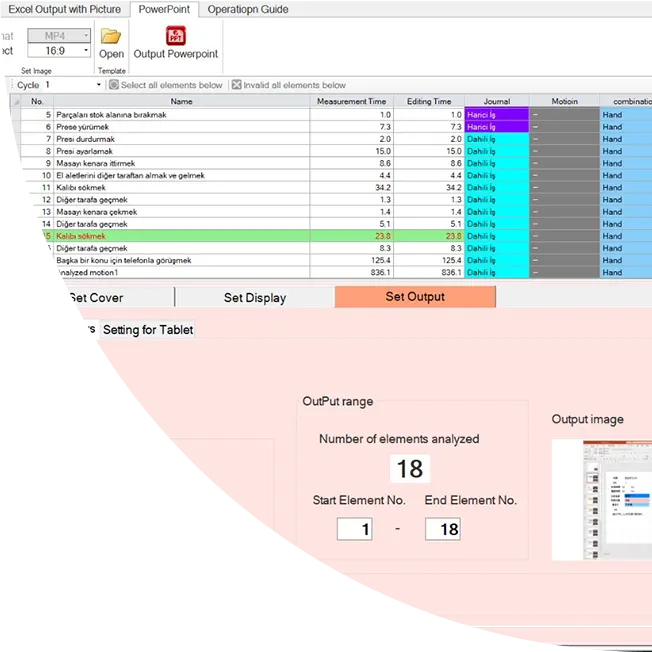

Start the process by recording a video, then watch and analyze it to identify value-added and Kaizen needs; visualize the data with charts to detect the problem and compare it with improvement (Kaizen) steps, and finally, document the improvements by standardizing them.

Complete Time Prism Workflow